Essential Guidelines for Anti-Impact Film Selection

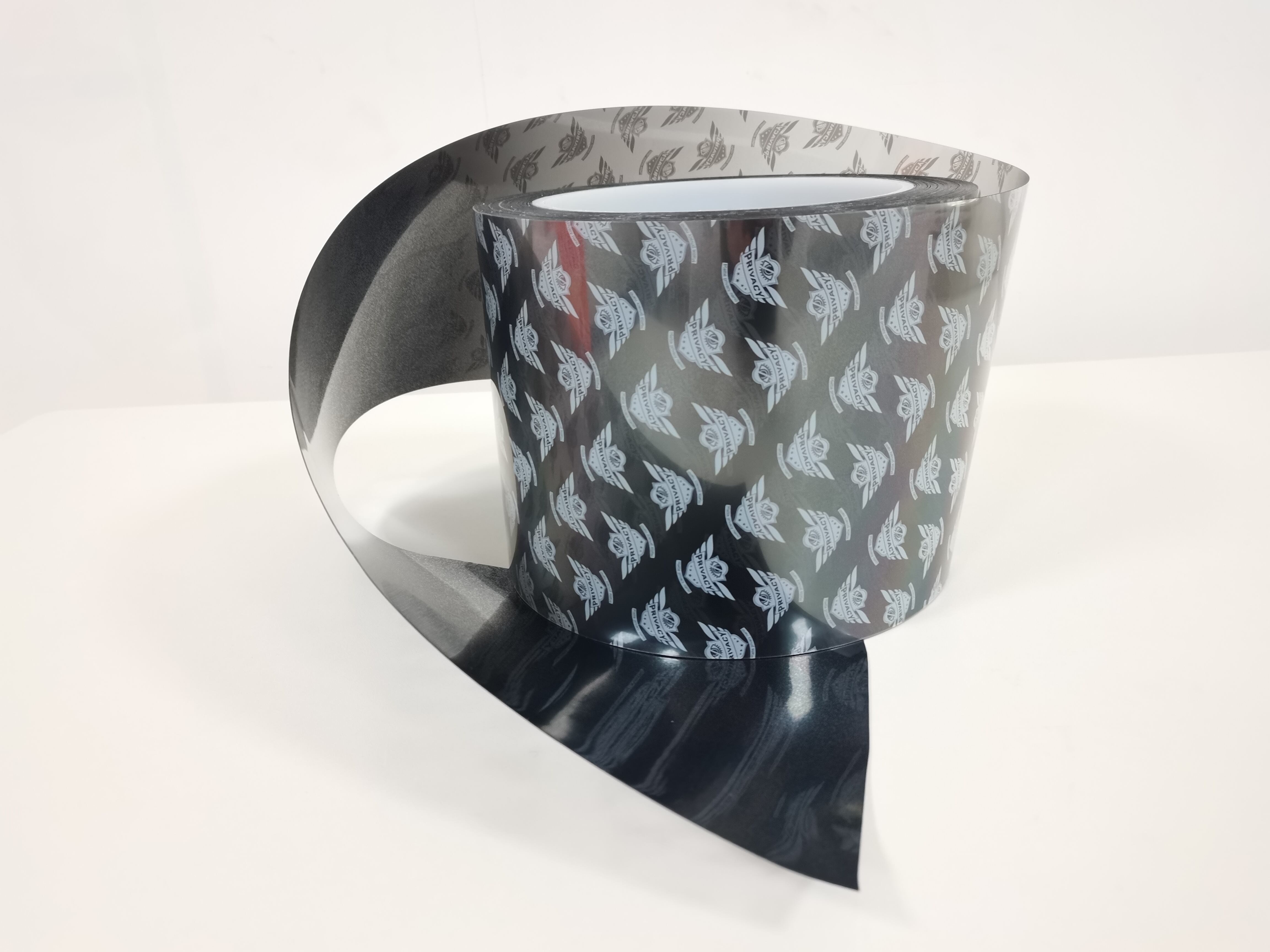

The selection of anti shock film rolls plays a crucial role in protecting valuable products during storage, transport, and handling. These specialized protective materials have become indispensable across various industries, from electronics to automotive parts. Understanding the key considerations when choosing anti shock film rolls can make the difference between adequate protection and potential damage to your goods.

Making an informed decision requires careful evaluation of multiple factors, including material composition, shock absorption capabilities, and specific application requirements. Let's explore the critical aspects that buyers need to consider to ensure they select the most suitable anti shock film rolls for their needs.

Material Properties and Performance Characteristics

Density and Thickness Specifications

The density and thickness of anti shock film rolls directly impact their protective capabilities. Higher density films typically offer superior shock absorption but may come at a premium cost. The optimal thickness depends on the specific application - delicate electronics might require thicker films compared to robust industrial components.

Professional buyers should evaluate the material's compression resistance and recovery rate. These properties determine how well the film maintains its protective qualities after repeated impacts. Quality anti shock film rolls should demonstrate consistent performance even after multiple compression cycles.

Impact Resistance and Energy Absorption

The primary function of anti shock film rolls is to absorb and dissipate impact energy. Different materials offer varying levels of shock absorption, measured through impact resistance testing. Advanced films incorporate specialized polymers that excel at converting kinetic energy into harmless heat during impact events.

Look for materials that provide documented impact resistance values and energy absorption rates. These specifications help ensure the selected film meets your specific protection requirements. Premium anti shock film rolls often feature multi-layer constructions that optimize both impact resistance and overall durability.

Environmental Considerations and Durability

Temperature and Humidity Resistance

Anti shock film rolls must maintain their protective properties across various environmental conditions. Temperature fluctuations and humidity levels can significantly affect film performance. Select materials rated for your specific operating environment, considering both storage and transit conditions.

High-quality anti shock film rolls incorporate stabilizers and additives that enhance their resistance to environmental factors. This ensures consistent protection regardless of seasonal changes or varying climate zones during transportation.

Chemical Compatibility and Shelf Life

Consider the chemical compatibility between the film and the products it will protect. Some materials may react adversely with certain chemicals or surface treatments. Leading manufacturers provide detailed compatibility guides for their anti shock film rolls.

The shelf life of the film material is another crucial factor. Premium products maintain their protective properties for extended periods, offering better value for bulk purchases. Always check the manufacturer's storage recommendations and expiration dates.

Application-Specific Requirements

Customization Options

Different applications may require specific dimensions or properties in anti shock film rolls. Consider manufacturers offering customization options such as custom widths, lengths, or surface treatments. This flexibility ensures optimal protection while minimizing waste and application time.

Some suppliers provide specialized anti shock film rolls with enhanced features like anti-static properties or UV protection. These additional characteristics can be valuable for specific industries or applications where standard films might fall short.

Ease of Application and Handling

The practical aspects of working with anti shock film rolls shouldn't be overlooked. Consider factors like roll weight, ease of dispensing, and application method. User-friendly features can significantly impact operational efficiency and worker satisfaction.

Look for materials that offer consistent unwinding and minimal static build-up during application. Some advanced anti shock film rolls feature special surface treatments that facilitate easier handling while maintaining protective properties.

Cost Considerations and Value Assessment

Total Cost of Ownership

While initial purchase price is important, evaluate the total cost of ownership when selecting anti shock film rolls. Consider factors like material efficiency, application labor costs, and potential waste. Higher quality films might offer better value through reduced material consumption and improved protection.

Calculate the cost per protected unit to make meaningful comparisons between different options. Premium anti shock film rolls often deliver better economics through superior protection rates and reduced damage claims.

Quality Certifications and Warranties

Reputable manufacturers back their anti shock film rolls with appropriate certifications and warranties. These assurances protect your investment and ensure consistent quality. Look for suppliers who maintain rigorous quality control standards and offer clear warranty terms.

Industry-specific certifications can be particularly important for regulated sectors. Ensure the selected materials meet all relevant standards and compliance requirements for your application.

Frequently Asked Questions

How long do anti shock film rolls typically last in storage?

High-quality anti shock film rolls generally maintain their protective properties for 12-24 months when stored under recommended conditions. Proper storage includes keeping the materials in a controlled environment away from direct sunlight and extreme temperatures.

Can anti shock film rolls be recycled?

Many modern anti shock film rolls are designed with recyclability in mind. Look for products made from recyclable materials and check with local recycling facilities for specific acceptance criteria. Some manufacturers offer take-back programs for their used materials.

What testing standards should buyers look for?

Key testing standards include impact resistance (ASTM D3763), compression set (ASTM D395), and environmental resistance tests. Reputable manufacturers provide detailed test results and certifications for their anti shock film rolls.

How do weather conditions affect the performance of anti shock film rolls?

Extreme temperatures and humidity can impact the performance of some anti shock film rolls. Premium materials are engineered to maintain consistent protection across a wide range of environmental conditions, typically from -40°C to +60°C (-40°F to +140°F).