The Evolution of Screen Protection Technology in Modern Smartphones

In the ever-evolving world of smartphone manufacturing, screen protection has become a critical component that can make or break a device's success. As devices become increasingly sophisticated, the demand for superior screen protection solutions has led to groundbreaking innovations, with TPH hydrogel membrane emerging as a game-changing technology. This revolutionary material has captured the attention of smartphone OEMs worldwide, offering unprecedented advantages that traditional screen protectors simply cannot match.

Understanding TPH Hydrogel Membrane Technology

Chemical Composition and Structure

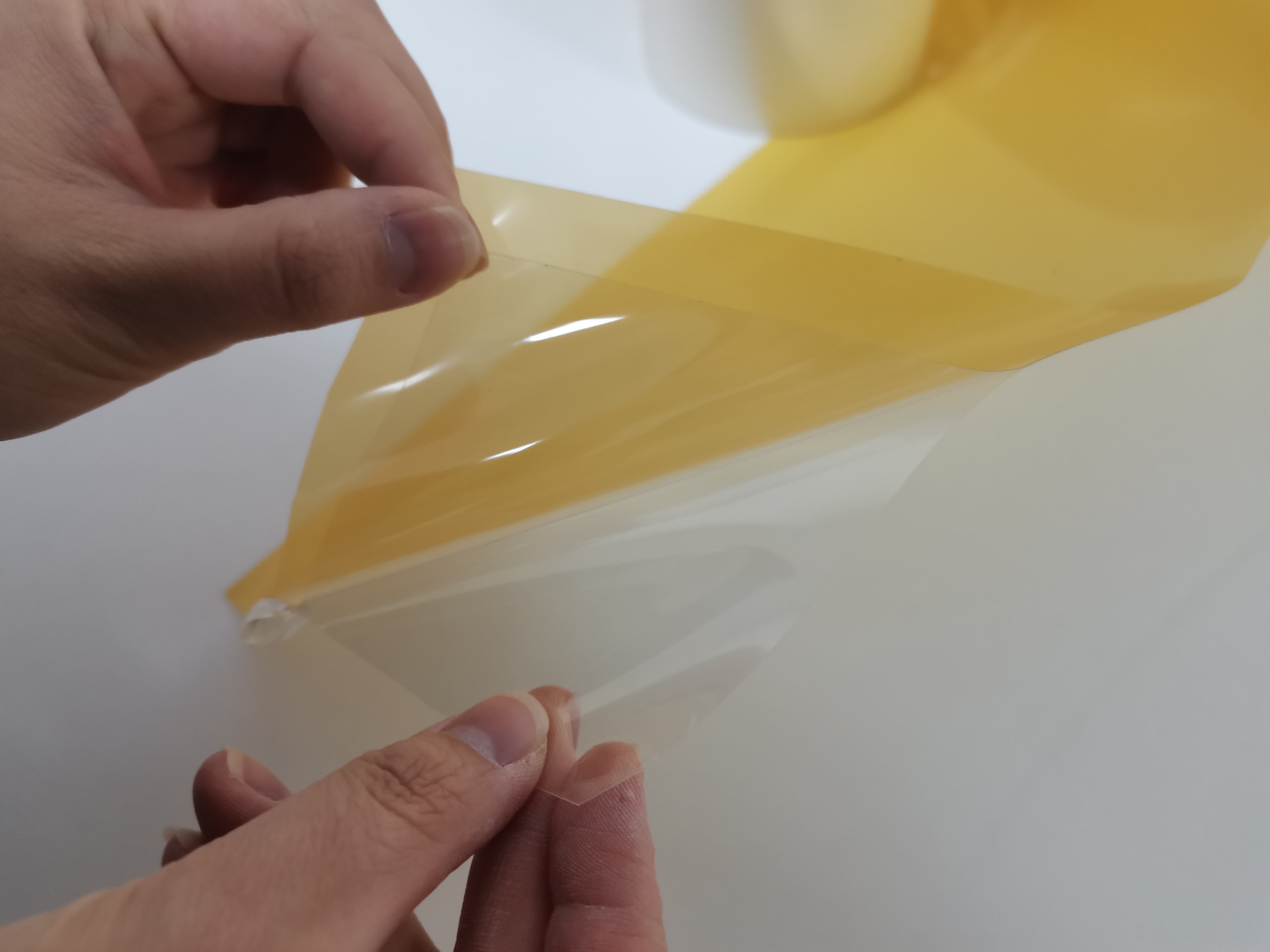

TPH hydrogel membrane represents a significant leap forward in material science. Composed of thermoplastic polyurethane and hydrogel polymers, this advanced material creates a unique molecular structure that combines flexibility with durability. The cross-linked polymer network allows for exceptional shock absorption while maintaining optical clarity, making it an ideal choice for smartphone screen protection.

The material's molecular arrangement enables it to self-heal minor scratches and abrasions, a feature that sets it apart from conventional screen protectors. This self-healing property is achieved through the material's ability to reform molecular bonds at room temperature, effectively erasing surface damage over time.

Manufacturing Process Excellence

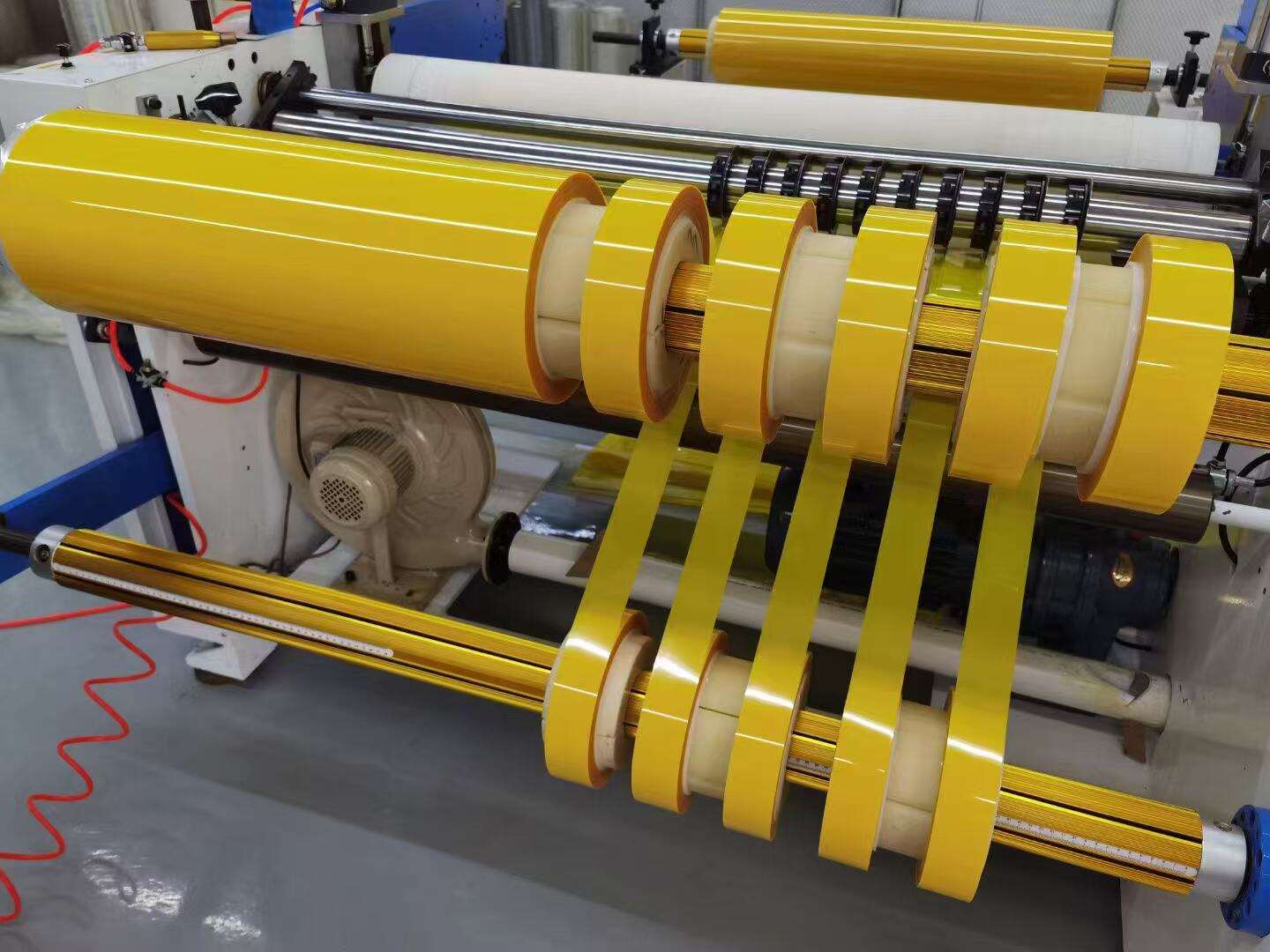

The production of TPH hydrogel membrane involves a sophisticated manufacturing process that ensures consistent quality and performance. Advanced clean room facilities and precision equipment are utilized to create ultra-thin layers of the material while maintaining perfect optical transparency. The controlled environment prevents contamination and ensures that each batch meets rigorous quality standards.

Quality control measures throughout the manufacturing process include thorough testing for optical clarity, adhesion strength, and impact resistance. This attention to detail results in a premium product that meets the exacting standards of smartphone OEMs.

Superior Performance Characteristics

Enhanced Protection Features

TPH hydrogel membrane excels in providing comprehensive protection for smartphone displays. The material offers superior shock absorption, effectively dispersing impact energy across its surface to prevent screen damage. Its unique molecular structure allows it to absorb and distribute force more efficiently than traditional tempered glass or PET film protectors.

The material's self-healing capabilities significantly extend the lifespan of the screen protector, maintaining a pristine appearance for longer periods. Minor scratches and scuffs disappear within hours, ensuring that the device's display remains clear and attractive throughout its lifetime.

Optical and Touch Performance

One of the most remarkable aspects of TPH hydrogel membrane is its exceptional optical clarity. With a light transmission rate exceeding 99%, it ensures that display quality remains uncompromised. The material's refractive index closely matches that of smartphone screens, minimizing interference with display visibility and color accuracy.

Touch sensitivity is another area where TPH hydrogel membrane shines. Its ultra-thin profile and excellent conductivity ensure that touch response remains precise and immediate. Users experience no lag or decreased sensitivity, making it ideal for gaming and other touch-intensive applications.

Integration Benefits for OEM Projects

Manufacturing Efficiency

TPH hydrogel membrane offers significant advantages in the manufacturing process. Its flexible nature allows for easier application during assembly, reducing installation time and minimizing the risk of bubbles or misalignment. The material's forgiving nature during application translates to higher yield rates and lower production costs.

The material's compatibility with automated application processes further streamlines manufacturing operations. This efficiency in production line integration makes it an attractive option for high-volume smartphone production.

Cost-Effective Long-term Solutions

While the initial investment in TPH hydrogel membrane technology may be higher than traditional solutions, the long-term cost benefits are substantial. The material's durability and self-healing properties reduce warranty claims and customer complaints related to screen protection issues. This translates to lower after-sales service costs and improved customer satisfaction.

The material's resistance to yellowing and degradation ensures that devices maintain their aesthetic appeal throughout their lifecycle, contributing to stronger brand reputation and customer loyalty.

Environmental and Sustainability Advantages

Eco-friendly Production Process

TPH hydrogel membrane production adheres to strict environmental standards, utilizing eco-friendly manufacturing processes that minimize waste and energy consumption. The material's production generates fewer harmful byproducts compared to traditional screen protection solutions, aligning with growing environmental concerns in the electronics industry.

The manufacturing process incorporates recycling systems for production waste, further reducing environmental impact. This commitment to sustainability resonates with environmentally conscious consumers and helps OEMs meet their corporate social responsibility goals.

Product Lifecycle Benefits

The extended lifespan of TPH hydrogel membrane contributes to reduced electronic waste. Its durability means fewer replacements are needed over the life of a device, reducing the environmental impact of screen protector disposal. The material's ability to self-heal also means fewer protectors end up in landfills due to minor damage.

As sustainability becomes increasingly important to consumers and regulators, the eco-friendly aspects of TPH hydrogel membrane provide OEMs with a competitive advantage in the marketplace.

Frequently Asked Questions

How long does the self-healing feature of TPH hydrogel membrane last?

The self-healing capabilities of TPH hydrogel membrane remain effective throughout the typical lifespan of a smartphone, usually 2-3 years under normal usage conditions. The material continuously maintains its ability to repair minor scratches and surface marks, ensuring long-lasting protection.

Can TPH hydrogel membrane be applied to curved smartphone screens?

Yes, the flexible nature of TPH hydrogel membrane makes it ideal for curved displays. Its unique molecular structure allows it to conform perfectly to curved surfaces while maintaining all protective properties and touch sensitivity.

What makes TPH hydrogel membrane more cost-effective than traditional screen protectors?

While the initial cost may be higher, TPH hydrogel membrane's durability, self-healing properties, and longer lifespan result in reduced warranty claims and replacement needs. This leads to lower total ownership costs for both manufacturers and end-users.

How does TPH hydrogel membrane compare to tempered glass in terms of impact protection?

TPH hydrogel membrane offers superior shock absorption through its flexible structure, distributing impact force more effectively than rigid tempered glass. While tempered glass may shatter under strong impact, TPH hydrogel membrane maintains its integrity while protecting the screen underneath.

Table of Contents

- The Evolution of Screen Protection Technology in Modern Smartphones

- Understanding TPH Hydrogel Membrane Technology

- Superior Performance Characteristics

- Integration Benefits for OEM Projects

- Environmental and Sustainability Advantages

-

Frequently Asked Questions

- How long does the self-healing feature of TPH hydrogel membrane last?

- Can TPH hydrogel membrane be applied to curved smartphone screens?

- What makes TPH hydrogel membrane more cost-effective than traditional screen protectors?

- How does TPH hydrogel membrane compare to tempered glass in terms of impact protection?