The Rising Demand for Advanced Hydrogel Solutions in Global Markets

The healthcare and biotechnology sectors have witnessed a remarkable shift towards innovative materials that offer enhanced functionality and adaptability. Among these groundbreaking solutions, customisable hydrogel membrane has emerged as a leading choice for researchers, medical professionals, and industry specialists worldwide. This versatile material combines exceptional properties with the ability to be tailored for specific applications, making it increasingly valuable across diverse fields.

As global markets continue to evolve, the demand for sophisticated biomaterials that can meet precise requirements has grown exponentially. Customisable hydrogel membrane stands out due to its unique combination of flexibility, biocompatibility, and adaptable properties, positioning it as a preferred choice for numerous applications ranging from medical devices to advanced wound care solutions.

Essential Properties and Characteristics

Advanced Material Composition

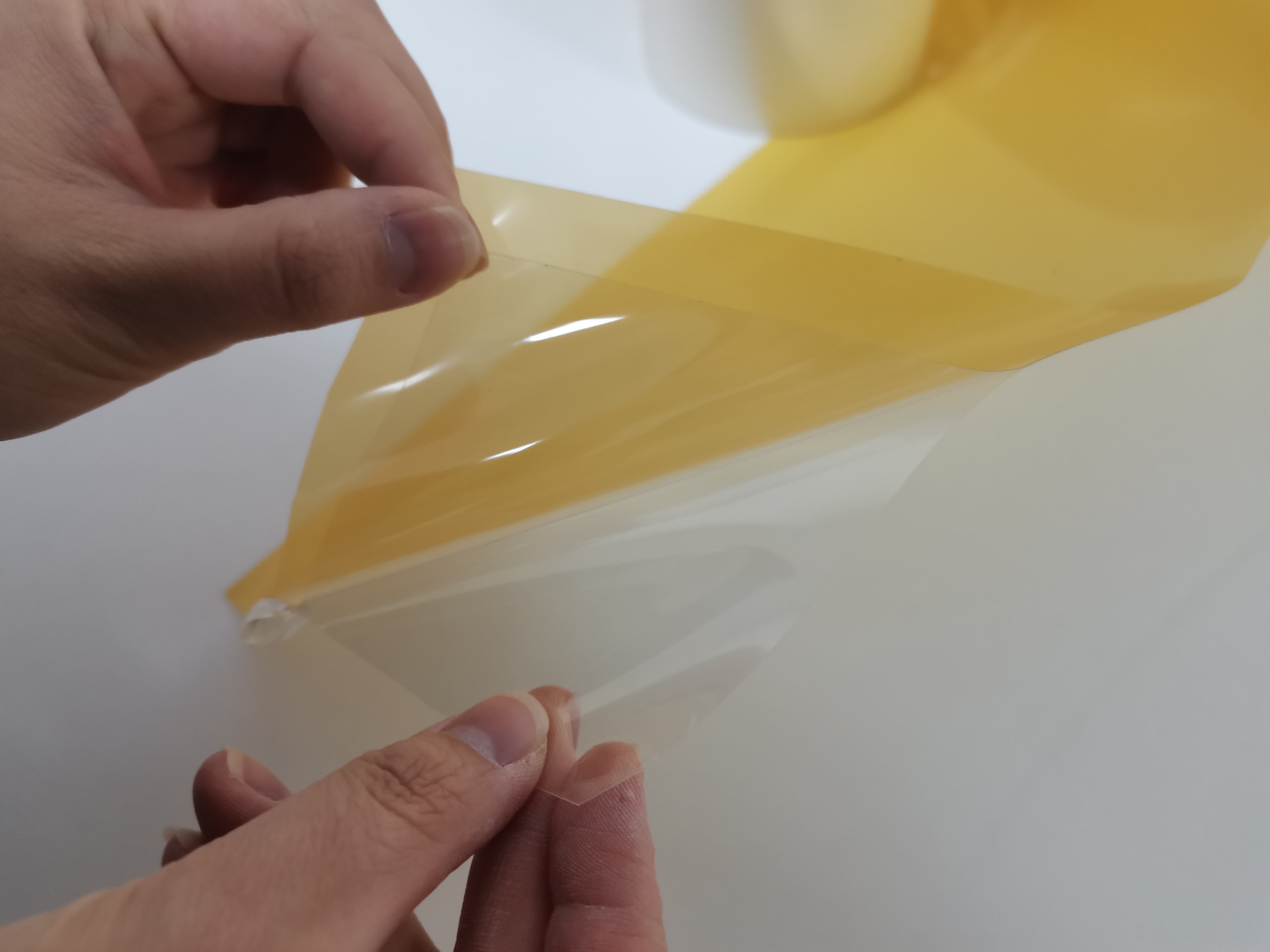

At its core, customisable hydrogel membrane consists of three-dimensional networks of hydrophilic polymer chains. These networks can absorb and retain significant amounts of water while maintaining their structural integrity. The material's composition can be precisely engineered to achieve specific physical and chemical properties, making it exceptionally versatile for various applications.

The polymer networks within the customisable hydrogel membrane can be modified through different crosslinking methods, allowing for precise control over properties such as mechanical strength, degradation rate, and water content. This level of customization enables manufacturers to create membranes that perfectly match the requirements of specific applications.

Biocompatibility and Safety Features

One of the most compelling aspects of customisable hydrogel membrane is its outstanding biocompatibility. The material's ability to mimic natural tissue properties makes it highly suitable for medical applications. Its non-toxic nature and minimal risk of adverse reactions have made it a preferred choice in tissue engineering and regenerative medicine.

The safety profile of customisable hydrogel membrane is further enhanced by its controlled degradation characteristics. Manufacturers can adjust the degradation rate to match the healing process or application requirements, ensuring optimal performance while maintaining safety standards.

Applications Across Industries

Medical Device Integration

The integration of customisable hydrogel membrane in medical devices has revolutionized various therapeutic approaches. From drug delivery systems to tissue scaffolds, the material's adaptable nature allows for precise control over release kinetics and mechanical properties. This versatility has led to improved patient outcomes and more effective treatment strategies.

Medical device manufacturers particularly value the ability to customize the membrane's properties according to specific device requirements. Whether it's controlling drug release rates or providing specific mechanical support, the adaptability of customisable hydrogel membrane makes it an invaluable component in modern medical devices.

Wound Care Solutions

In the field of wound care, customisable hydrogel membrane has demonstrated remarkable effectiveness. Its ability to maintain a moist wound environment while allowing for gas exchange creates optimal conditions for healing. The material can be modified to incorporate antimicrobial properties or growth factors, further enhancing its therapeutic potential.

The customization options available with hydrogel membranes allow healthcare providers to select products specifically designed for different wound types and healing stages. This flexibility has contributed significantly to improved wound care outcomes and patient comfort.

Manufacturing and Customization Process

Production Technologies

The manufacturing of customisable hydrogel membrane involves sophisticated processes that ensure precise control over material properties. Advanced production technologies enable manufacturers to achieve consistent quality while maintaining the ability to customize various parameters. These technologies include photo-polymerization, chemical crosslinking, and advanced molding techniques.

Quality control measures throughout the production process ensure that each batch of customisable hydrogel membrane meets stringent specifications. This attention to detail has been crucial in gaining the trust of global buyers who require reliable and consistent products.

Customization Parameters

The ability to adjust multiple parameters during production makes customisable hydrogel membrane highly attractive to global buyers. Manufacturers can modify properties such as water content, mechanical strength, degradation rate, and surface chemistry to meet specific application requirements. This level of customization ensures optimal performance across different use cases.

The flexibility in customization extends to the incorporation of various bioactive molecules and functional groups, allowing for the development of application-specific solutions that address unique challenges in different fields.

Market Trends and Future Prospects

Global Market Growth

The market for customisable hydrogel membrane continues to expand as new applications emerge and existing ones evolve. Growing awareness of the material's benefits, coupled with increasing investment in research and development, has driven substantial market growth. Healthcare facilities, research institutions, and industrial users worldwide are increasingly recognizing the advantages of customizable hydrogel solutions.

Market analysts project continued growth in the coming years, driven by technological advancements and expanding applications across various sectors. The ability to customize properties according to specific needs remains a key factor in this growth trajectory.

Innovation and Research Developments

Ongoing research in the field of customisable hydrogel membrane continues to unveil new possibilities and applications. Scientists and engineers are exploring novel modification techniques and investigating potential uses in emerging fields such as 3D bioprinting and smart medical devices. These developments are expected to further enhance the material's value proposition for global buyers.

The focus on sustainable and environmentally friendly materials has also influenced research directions, with efforts being made to develop eco-conscious customisable hydrogel membrane solutions that maintain high performance standards.

Frequently Asked Questions

What makes customisable hydrogel membrane different from traditional materials?

Customisable hydrogel membrane offers unique advantages through its ability to be precisely tailored for specific applications, combining excellent biocompatibility with adjustable physical and chemical properties. Unlike traditional materials, it can be modified to achieve optimal performance in various environments while maintaining its essential characteristics.

How long does it take to develop a custom hydrogel membrane solution?

The development timeline for a custom hydrogel membrane solution typically ranges from several weeks to a few months, depending on the complexity of requirements and the extent of customization needed. This includes testing and validation phases to ensure the final product meets all specified parameters.

What are the storage requirements for customisable hydrogel membrane products?

Customisable hydrogel membrane products generally require controlled storage conditions, including specific temperature ranges and protection from direct sunlight. The exact requirements depend on the particular formulation and intended application, with proper storage ensuring maintained functionality and shelf life.