In today's technology-driven world, protecting electronic devices has become paramount for both consumers and businesses. The emergence of advanced materials like TPU hydrogel film has revolutionized device protection, offering superior durability and performance compared to traditional protective solutions. This innovative material combines the flexibility of thermoplastic polyurethane with the self-healing properties of hydrogel technology, creating an unprecedented level of protection for smartphones, tablets, and other electronic displays.

The protective film industry has witnessed significant advancements in recent years, with manufacturers continuously seeking materials that offer enhanced protection without compromising device functionality. TPU hydrogel film represents a breakthrough in this field, providing exceptional clarity, touch sensitivity, and long-term durability that extends device lifespan considerably. Understanding how this technology works and its impact on device longevity is crucial for manufacturers, distributors, and end-users looking to maximize their investment in electronic devices.

Understanding TPU Hydrogel Technology

Material Composition and Properties

TPU hydrogel film consists of a unique polymer structure that combines thermoplastic polyurethane with hydrogel components. This molecular arrangement creates a material that exhibits remarkable flexibility while maintaining structural integrity under various environmental conditions. The hydrogel component provides self-healing capabilities, allowing minor scratches and abrasions to disappear over time through molecular reorganization.

The thermoplastic polyurethane base offers excellent elasticity and resistance to wear, making the film highly durable against daily usage scenarios. This combination results in a protective layer that maintains its protective qualities throughout extended periods of use, unlike traditional materials that degrade rapidly under stress. The molecular structure also ensures optimal light transmission, preserving display clarity and color accuracy.

Manufacturing Process and Quality Control

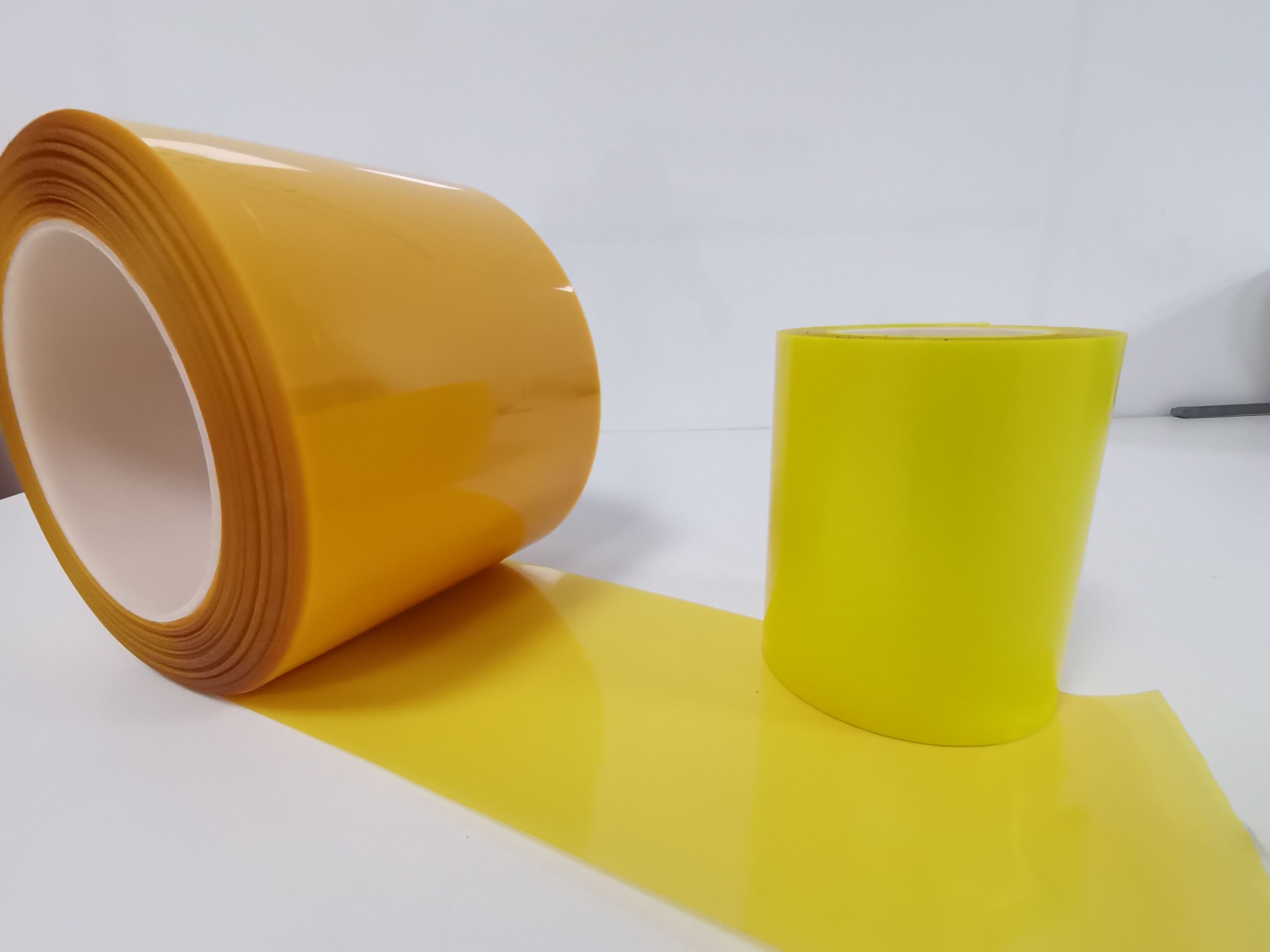

The production of high-quality TPU hydrogel film involves sophisticated manufacturing processes that ensure consistent material properties and performance. Advanced coating techniques are employed to create uniform thickness across the entire film surface, eliminating weak points that could compromise protection. Quality control measures include rigorous testing for adhesion strength, optical clarity, and environmental resistance.

Manufacturing facilities utilize clean room environments to prevent contamination during production, ensuring that the final product meets stringent quality standards. Each batch undergoes comprehensive testing protocols that evaluate scratch resistance, impact absorption, and long-term stability under various temperature and humidity conditions. This meticulous approach to manufacturing ensures that TPU hydrogel film delivers consistent performance across different applications and environments.

Protection Mechanisms and Device Longevity

Impact Absorption and Scratch Resistance

The primary mechanism through which TPU hydrogel film extends device longevity is its exceptional ability to absorb and distribute impact forces. When a device experiences drops or impacts, the film's polymer structure deforms elastically, absorbing kinetic energy that would otherwise transfer to the underlying screen or surface. This energy dissipation prevents crack formation and maintains the structural integrity of the protected device.

Scratch resistance is another critical factor in device longevity, as surface damage can compromise both functionality and aesthetics. The film's surface hardness and self-healing properties work together to resist everyday wear from keys, coins, and other common sources of scratches. When minor scratches do occur, the hydrogel component gradually fills these imperfections, restoring the surface to its original condition and maintaining optimal protection levels.

Environmental Protection and Stability

Environmental factors such as UV radiation, temperature fluctuations, and humidity can significantly impact device longevity. TPU hydrogel film provides a protective barrier against these elements, preventing degradation of underlying components and maintaining device performance over time. The film's UV resistance prevents yellowing and brittleness that commonly affect other protective materials, ensuring long-term clarity and protection.

Temperature stability is particularly important for electronic devices that operate in varying environmental conditions. The film maintains its protective properties across a wide temperature range, from sub-zero conditions to high-heat environments. This stability ensures consistent protection regardless of climate or usage conditions, contributing significantly to extended device lifespan and reliable performance.

Application Benefits and Performance Metrics

Touch Sensitivity and User Experience

One of the most significant advantages of TPU hydrogel film is its minimal impact on touch sensitivity and user experience. Unlike thicker protective solutions that can interfere with device functionality, this advanced material maintains nearly perfect touch responsiveness while providing superior protection. The film's thin profile and excellent electrical conductivity ensure that touchscreen devices continue to operate with precision and accuracy.

Users report no noticeable difference in device responsiveness when TPU hydrogel film protection is applied, making it an ideal solution for professional applications where performance cannot be compromised. The film's smooth surface texture also enhances the tactile experience, providing a premium feel that matches or exceeds the original device surface quality.

Installation and Maintenance Advantages

The installation process for TPU hydrogel film is significantly more forgiving than traditional protective films, thanks to its flexible nature and repositionable adhesive system. Bubble formation during installation is virtually eliminated due to the material's ability to conform to surface contours and expel trapped air naturally. This ease of installation reduces waste and ensures optimal protection from the moment of application.

Maintenance requirements are minimal once the film is properly installed, as the self-healing properties reduce the need for replacement due to minor damage. The film's resistance to oils, fingerprints, and other contaminants also simplifies cleaning and maintenance routines. Regular cleaning with standard solutions effectively removes accumulated debris without compromising the film's protective properties or optical clarity.

Industrial Applications and Market Impact

Commercial and Industrial Use Cases

Beyond consumer electronics, TPU hydrogel film has found extensive applications in commercial and industrial settings where device longevity is critical for operational efficiency. Medical equipment, industrial control panels, and automotive displays benefit significantly from the enhanced protection and extended lifespan that this technology provides. The film's biocompatibility and chemical resistance make it particularly suitable for healthcare applications where hygiene and durability are paramount.

Manufacturing facilities have adopted TPU hydrogel film for protecting expensive equipment interfaces and control systems, reducing replacement costs and minimizing downtime. The film's ability to withstand harsh industrial environments while maintaining clarity and functionality has made it an essential component in many industrial protection strategies.

Economic Benefits and Cost Effectiveness

The economic impact of using TPU hydrogel film extends far beyond the initial investment, as the extended device longevity significantly reduces total cost of ownership. Organizations report substantial savings in device replacement costs, repair expenses, and productivity losses associated with damaged equipment. The film's durability means fewer replacements are needed compared to traditional protective solutions, further enhancing cost effectiveness.

Return on investment calculations consistently demonstrate positive outcomes when TPU hydrogel film is implemented as part of a comprehensive device protection strategy. The combination of reduced replacement frequency, lower maintenance costs, and improved device reliability creates compelling economic benefits that justify the premium associated with this advanced protective technology.

Future Developments and Innovation Trends

Emerging Technologies and Enhancements

Research and development efforts continue to push the boundaries of TPU hydrogel film technology, with emerging innovations focusing on enhanced functionality and performance characteristics. Next-generation formulations incorporate advanced additives that provide additional benefits such as antimicrobial properties, enhanced self-healing capabilities, and improved environmental resistance. These developments promise even greater device longevity and protection in future applications.

Smart film technologies that integrate sensors and responsive materials are also being developed, potentially allowing TPU hydrogel film to provide real-time feedback about device condition and protection status. These innovations represent the next evolution in protective film technology, combining traditional protection with intelligent monitoring capabilities.

Market Growth and Industry Adoption

The global market for TPU hydrogel film continues to expand as more industries recognize the benefits of this advanced protective technology. Growth is driven by increasing device complexity, higher replacement costs, and growing awareness of the importance of proactive protection strategies. Market projections indicate continued strong demand across multiple sectors, with particular growth expected in emerging markets and new application areas.

Industry adoption rates are accelerating as manufacturers and distributors recognize the competitive advantages associated with offering superior protection solutions. Companies that incorporate TPU hydrogel film into their product offerings report improved customer satisfaction, reduced warranty claims, and enhanced brand reputation, driving further market expansion and technology adoption.

FAQ

How long does TPU hydrogel film typically last on a device

TPU hydrogel film typically maintains its protective properties for 2-3 years under normal usage conditions, significantly longer than traditional protective films. The exact lifespan depends on usage patterns, environmental conditions, and application quality. The self-healing properties help extend the effective life by continuously repairing minor damage, while the material's inherent stability prevents degradation from UV exposure and temperature variations. Many users report satisfactory protection for even longer periods, making it a cost-effective long-term solution.

Can TPU hydrogel film be removed without damaging the device

Yes, TPU hydrogel film can be safely removed without damaging the underlying device surface when proper removal techniques are employed. The adhesive system is designed to provide strong attachment during use while allowing clean removal when necessary. Gentle heating with a hair dryer softens the adhesive, making removal easier and reducing the risk of residue. Any remaining adhesive can be safely removed using appropriate cleaning solutions without affecting the device's original surface or functionality.

Does TPU hydrogel film affect wireless charging or signal reception

High-quality TPU hydrogel film has minimal impact on wireless charging efficiency or signal reception when properly manufactured and applied. The thin profile and low dielectric constant of the material ensure that electromagnetic signals pass through with negligible interference. Wireless charging typically operates at 95-100% efficiency with the film in place, while cellular and WiFi signals experience no measurable degradation. However, it's important to source film from reputable manufacturers who specifically design their products to maintain device functionality.

What makes TPU hydrogel film superior to tempered glass protectors

TPU hydrogel film offers several advantages over tempered glass protectors, including superior impact absorption, edge-to-edge coverage, and self-healing capabilities. While tempered glass provides excellent scratch resistance, it can shatter under impact and doesn't conform to curved surfaces. TPU hydrogel film absorbs impact energy elastically, preventing crack propagation to the underlying screen. Additionally, the film's flexibility allows complete coverage of curved edges and complex surface geometries, providing comprehensive protection that glass cannot match.