Modern transportation relies heavily on clear visibility for safe operation, yet weather conditions frequently compromise driver safety through condensation and fogging on mirrors and windows. Anti-fog film technology has emerged as a critical solution for maintaining optimal visibility across various automotive and motorcycle applications. This innovative protective layer addresses the persistent challenge of moisture accumulation that can obstruct crucial sight lines during critical driving moments.

The automotive industry has recognized the essential role of clear vision systems in preventing accidents and ensuring passenger safety. When mirrors and protective surfaces become obscured by fog, drivers face significantly increased risks during lane changes, reversing maneuvers, and general navigation. Professional-grade anti-fog solutions provide a reliable barrier against moisture accumulation while maintaining the optical clarity necessary for safe vehicle operation.

Understanding the mechanics and applications of anti-fog technology enables fleet managers, automotive professionals, and individual drivers to make informed decisions about visibility enhancement products. These specialized films offer long-term protection that extends beyond temporary solutions, providing consistent performance across diverse environmental conditions and operational scenarios.

Understanding Anti-Fog Technology Fundamentals

Scientific Principles Behind Fog Formation

Fog formation occurs when warm, humid air contacts cooler surfaces, causing water vapor to condense into microscopic droplets that scatter light and reduce visibility. This phenomenon is particularly problematic on vehicle mirrors, helmet visors, and protective glass surfaces where clear vision is essential for safety. The temperature differential between interior and exterior environments creates ideal conditions for rapid condensation formation.

Traditional approaches to fog prevention often involve temporary measures such as wiping or heating, but these methods provide only short-term relief and may damage sensitive surfaces. Advanced anti-fog film technology addresses the root cause by modifying the surface characteristics to prevent water droplet formation while maintaining optical transparency and durability.

The molecular structure of professional anti-fog coatings creates a hydrophilic surface that spreads water into an ultra-thin, invisible layer rather than allowing droplet formation. This scientific approach ensures consistent visibility even under extreme temperature variations and high humidity conditions commonly encountered in automotive applications.

Material Composition and Manufacturing Standards

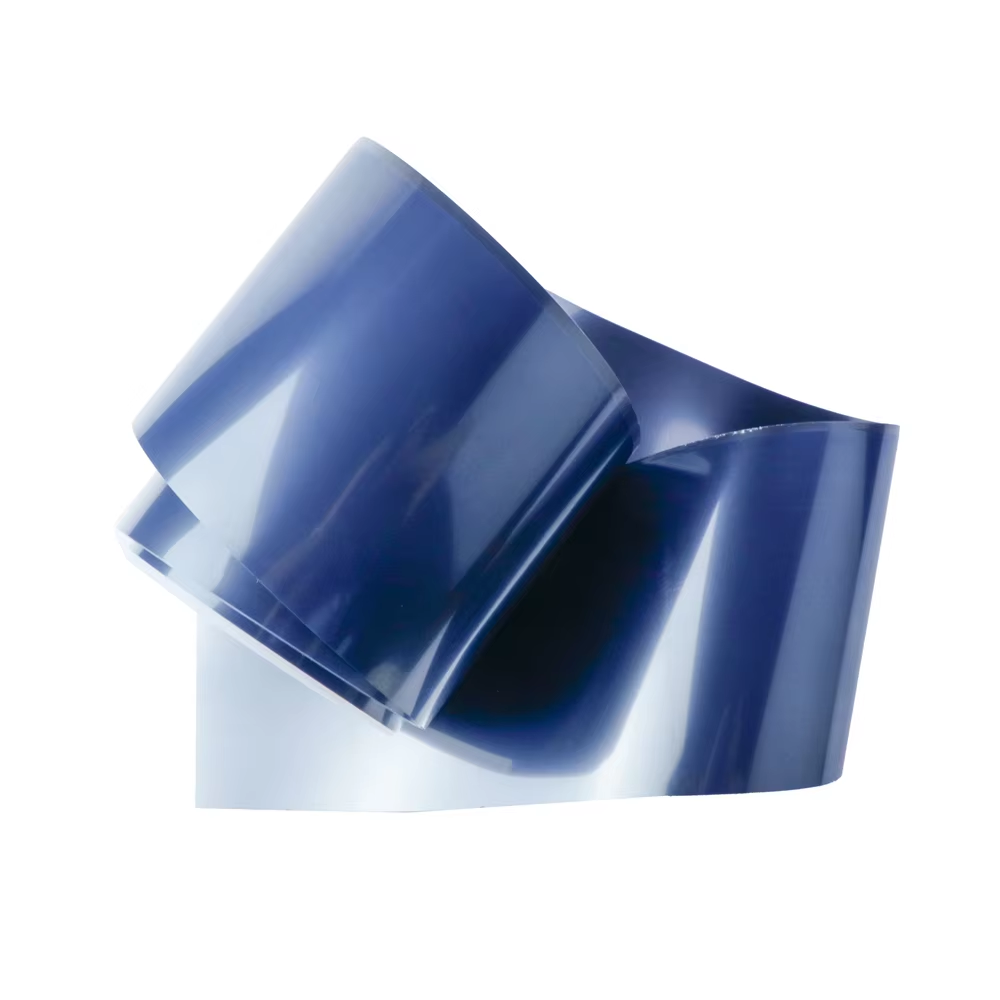

High-quality anti-fog film incorporates specialized polymer materials engineered to withstand automotive environments while maintaining their fog-resistant properties over extended periods. The manufacturing process involves precise layering of hydrophilic compounds that bond permanently to the substrate without affecting optical clarity or surface durability.

Professional-grade products undergo rigorous testing protocols to ensure performance standards meet automotive industry requirements for visibility, adhesion strength, and environmental resistance. These specifications guarantee reliable operation across temperature ranges from sub-zero conditions to extreme heat, making them suitable for global automotive applications.

Quality control measures during production ensure consistent thickness distribution and uniform coating application, preventing optical distortions that could compromise safety. Advanced manufacturing techniques produce films with excellent conformability to curved surfaces, essential for proper installation on vehicle mirrors and complex automotive glass shapes.

Driver Safety Enhancement Through Improved Visibility

Critical Visibility Scenarios in Automotive Applications

Driver safety depends fundamentally on maintaining clear sight lines through mirrors and windows during various weather conditions and operational scenarios. Anti-fog film applications prove most critical during early morning drives when temperature differentials are greatest, rainy conditions with high humidity, and winter weather when heating systems create significant interior-exterior temperature variations.

Emergency situations require immediate visibility without the delay of manual clearing procedures that can compromise reaction times. Professional drivers, including commercial vehicle operators and emergency responders, particularly benefit from reliable anti-fog protection that maintains consistent visibility throughout extended operational periods without maintenance interruptions.

Lane change maneuvers represent one of the most dangerous driving activities, with side mirror visibility being crucial for safe execution. When mirrors become fogged, drivers may miss approaching vehicles or misjudge distances, leading to potentially catastrophic collisions. Reliable anti-fog protection eliminates these visibility gaps during critical decision-making moments.

Accident Prevention Through Enhanced Mirror Performance

Statistical analysis of traffic accidents reveals that visibility-related factors contribute significantly to collision rates, particularly during adverse weather conditions when fogging is most prevalent. Professional anti-fog treatments reduce these risks by ensuring mirrors maintain optimal clarity regardless of environmental conditions, enabling drivers to make informed decisions based on accurate visual information.

Parking and reversing operations become significantly safer with fog-free mirror visibility, as drivers can accurately assess distances and identify obstacles or pedestrians in their path. This enhanced visibility is particularly valuable in commercial applications where larger vehicles have extensive blind spots that require maximum mirror effectiveness for safe operation.

Multi-vehicle convoy operations, common in commercial transportation and emergency services, depend on clear mirror visibility for maintaining proper following distances and coordinating lane changes. Anti-fog protection ensures consistent visual communication between vehicles, reducing the risk of chain-reaction accidents caused by visibility-impaired driving decisions.

Comfort and Convenience Benefits for Daily Driving

Elimination of Manual Maintenance Requirements

Traditional fog management requires frequent manual intervention, including wiping mirrors and adjusting ventilation systems, which can distract drivers from road monitoring and create safety hazards. Professional anti-fog film eliminates these maintenance requirements by providing automatic fog prevention that operates continuously without driver intervention or system activation.

Time savings from reduced mirror maintenance become particularly significant for professional drivers who operate vehicles for extended periods daily. Fleet operators report substantial productivity improvements when drivers no longer need to interrupt routes for visibility maintenance, resulting in improved schedule adherence and reduced operational costs.

The convenience factor extends beyond mere time savings to include reduced physical strain and improved focus on primary driving tasks. Drivers can maintain attention on traffic conditions rather than managing visibility issues, contributing to overall driving comfort and reducing fatigue during long journeys.

Enhanced Driving Experience Across Weather Conditions

Consistent mirror performance across diverse weather conditions creates a more predictable and comfortable driving environment where visibility remains reliable regardless of external factors. This consistency reduces driver stress and anxiety associated with weather-related visibility challenges, contributing to more confident and safer driving behaviors.

Climate control systems operate more efficiently when not competing with fogging issues, as drivers can optimize temperature settings for comfort rather than fog prevention. This improved efficiency results in better fuel economy and reduced wear on HVAC components while maintaining superior cabin comfort levels.

Professional applications benefit from improved driver satisfaction and reduced training requirements, as operators can focus on core job responsibilities rather than learning complex fog management techniques. This streamlined approach to vehicle operation contributes to improved job performance and reduced operator turnover in transportation industries.

Installation and Performance Considerations

Proper Application Techniques for Optimal Results

Successful anti-fog film installation requires careful surface preparation to ensure proper adhesion and long-term performance. The process begins with thorough cleaning using appropriate solvents to remove all traces of oils, residues, and contaminants that could interfere with film bonding or create optical distortions that compromise visibility.

Professional installation techniques involve controlled environmental conditions to prevent dust contamination during application and ensure uniform film placement without air bubbles or wrinkles. Proper squeegee techniques and application pressures are essential for achieving optimal adhesion while preventing damage to the anti-fog coating during installation.

Quality control verification includes testing for proper adhesion, optical clarity, and immediate fog resistance before vehicle return to service. Professional installers typically provide performance guarantees and follow-up inspections to ensure long-term satisfaction with anti-fog film performance under actual operating conditions.

Long-Term Durability and Maintenance Requirements

High-quality anti-fog film products are engineered for extended service life under normal automotive operating conditions, with performance warranties typically ranging from several months to multiple years depending on application and environmental factors. Proper maintenance involves gentle cleaning with recommended solutions to preserve the anti-fog coating effectiveness.

Environmental factors such as extreme temperatures, UV exposure, and chemical exposure from cleaning products can affect long-term performance, making product selection and maintenance procedures critical for maximizing return on investment. Professional-grade films incorporate UV stabilizers and chemical resistance properties to maintain performance under harsh operating conditions.

Performance monitoring involves periodic evaluation of fog resistance effectiveness and optical clarity to determine when replacement may be necessary. Most professional applications maintain excellent performance throughout their intended service life when properly installed and maintained according to manufacturer specifications.

Industry Applications and Market Benefits

Commercial Transportation and Fleet Management

Fleet operators increasingly recognize anti-fog film as an essential safety investment that reduces accident liability while improving operational efficiency. Large transportation companies report measurable improvements in driver performance ratings and reduced insurance claims when vehicles are equipped with professional-grade visibility enhancement products.

Commercial vehicle applications include long-haul trucking, delivery services, emergency response vehicles, and public transportation where driver visibility directly impacts public safety and service reliability. The investment in anti-fog protection typically generates positive returns through reduced maintenance costs, improved schedule adherence, and decreased accident-related expenses.

Regulatory compliance in some transportation sectors requires maintaining specific visibility standards that anti-fog film helps achieve consistently across diverse operating conditions. Professional fleet managers incorporate these products into standard vehicle specifications to ensure compliance and maintain competitive safety ratings.

Motorcycle and Recreational Vehicle Markets

Motorcycle applications present unique challenges where helmet visor fogging can create immediate safety hazards during critical maneuvering situations. Anti-fog film technology adapted for curved helmet surfaces provides essential protection for riders operating in varying weather conditions and temperature environments.

Recreational vehicle applications include off-road vehicles, marine craft, and specialty equipment where traditional fog management systems may be impractical or unavailable. These applications often operate in extreme environmental conditions where reliable visibility protection becomes essential for operator safety and equipment protection.

Performance requirements in recreational applications often exceed standard automotive specifications due to exposure to saltwater, extreme temperatures, and high-vibration environments. Specialized anti-fog film formulations address these challenges while maintaining the optical clarity and durability necessary for safe operation in demanding conditions.

FAQ

How long does anti-fog film typically last on vehicle mirrors

Professional-grade anti-fog film typically maintains effective performance for 12-24 months under normal operating conditions, with some premium products offering extended durability up to 36 months. Performance life depends on environmental factors such as temperature extremes, UV exposure, cleaning frequency, and the quality of installation. Regular gentle cleaning with appropriate solutions helps maximize service life, while harsh chemicals or abrasive cleaning methods can reduce effectiveness.

Can anti-fog film be removed without damaging the mirror surface

Quality anti-fog films are designed for clean removal without leaving residue or damaging the underlying mirror surface when proper removal techniques are employed. The removal process typically involves gentle heating to soften the adhesive followed by careful peeling at appropriate angles. Any remaining adhesive residue can be safely removed using recommended solvents that do not damage mirror coatings or substrates.

Does anti-fog film affect mirror optical clarity or cause distortions

Professional anti-fog films are engineered to maintain excellent optical clarity with minimal impact on reflection quality or color accuracy. High-quality products undergo extensive optical testing to ensure distortion-free performance that meets automotive safety standards. Proper installation is crucial for maintaining optical quality, as air bubbles or improper alignment can create visual distortions that compromise mirror effectiveness.

Is anti-fog film compatible with heated mirror systems

Most professional anti-fog films are fully compatible with heated mirror systems and can actually enhance their effectiveness by providing fog protection during warm-up periods and backup protection if heating elements fail. The film materials are designed to withstand the temperature ranges generated by automotive heating systems without degradation or performance loss. Installation procedures may require specific techniques to ensure proper heat transfer and avoid interference with heating element operation.