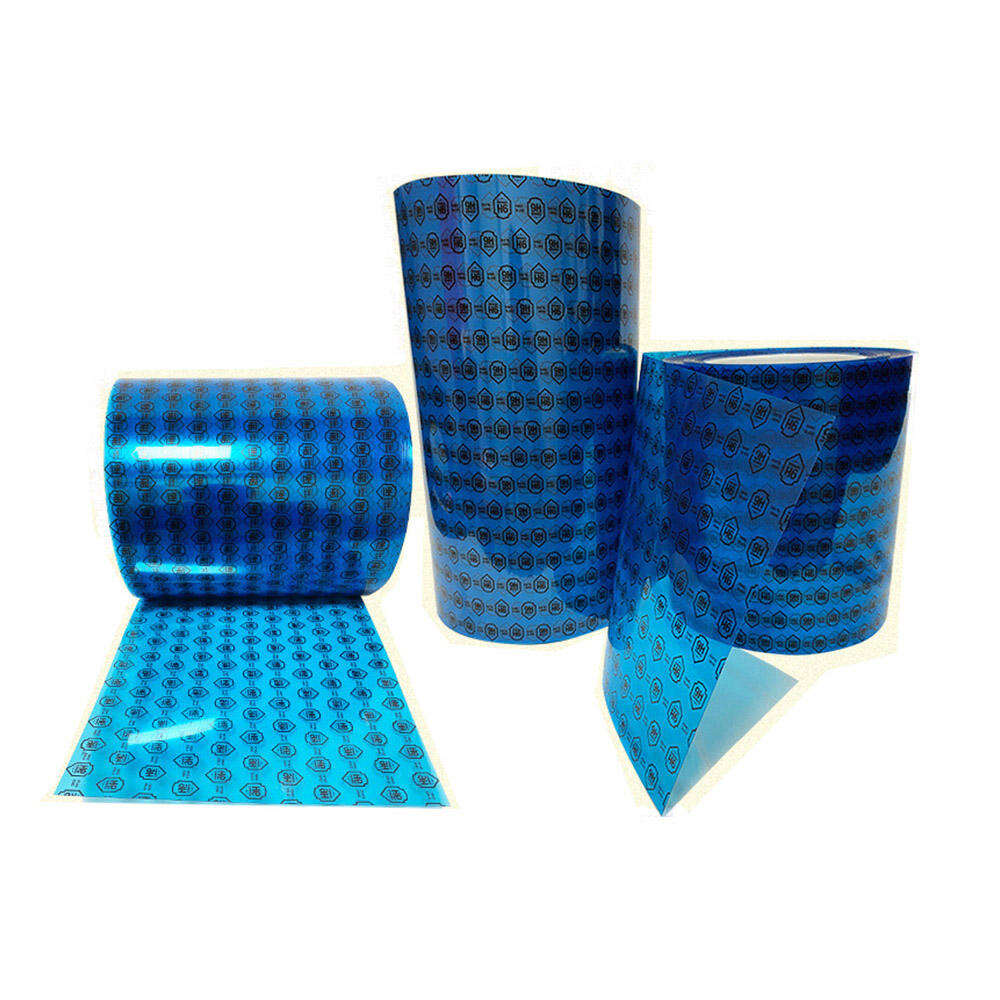

The global market for protective films has witnessed unprecedented growth, with anti shock high clear PET film emerging as a critical component across numerous industries. This specialized material combines exceptional clarity with superior impact resistance, making it an indispensable solution for applications requiring both visual transparency and physical protection. As manufacturers continue to innovate and develop more sophisticated products, the demand for high-performance protective films continues to surge across diverse sectors.

The unique properties of this advanced material stem from its polyethylene terephthalate composition, which has been engineered to provide exceptional durability while maintaining optical clarity. Unlike traditional protective solutions, these films offer superior scratch resistance, impact absorption, and long-term stability without compromising visual quality. The manufacturing process involves precision coating techniques that ensure uniform thickness and consistent performance characteristics across large surface areas.

Consumer Electronics and Mobile Device Manufacturing

Smartphone and Tablet Protection Solutions

The consumer electronics industry represents one of the largest markets for anti shock high clear PET film applications. Smartphone manufacturers increasingly rely on these protective films to safeguard delicate touchscreens during production, shipping, and retail display. The films provide temporary protection against scratches, dust, and minor impacts while allowing full visibility of the underlying display technology. Premium devices often incorporate multiple layers of protection, with specialized films designed for different stages of the manufacturing and distribution process.

Tablet computers and portable gaming devices benefit significantly from advanced protective film technology due to their larger screen surfaces and frequent handling. The clarity requirements for these applications are particularly stringent, as any optical distortion can negatively impact user experience. Manufacturers must balance protection levels with touch sensitivity, ensuring that the film thickness does not interfere with capacitive touch functionality or stylus precision.

Display Panel Manufacturing and Assembly

LCD and OLED display manufacturers utilize protective films throughout various production stages to prevent contamination and damage during assembly processes. The clean room environments required for display manufacturing demand materials that do not outgas or generate particulates that could compromise production quality. Anti shock films serve as temporary barriers during substrate preparation, backlight installation, and final quality control testing procedures.

The transition toward flexible and curved display technologies has created new challenges for protective film applications. Manufacturers require materials that can conform to complex geometries while maintaining their protective properties and optical clarity. Advanced formulations now incorporate improved flexibility characteristics that allow the films to bend and flex without cracking or losing adhesion to the underlying substrate.

Automotive Industry Applications

Interior Display and Infotainment Systems

Modern vehicles incorporate numerous display screens for navigation, entertainment, and vehicle monitoring systems. These displays require protection during vehicle assembly and transportation to prevent damage from manufacturing processes and environmental exposure. The automotive industry demands materials that can withstand temperature fluctuations, humidity variations, and exposure to various chemicals used in vehicle production.

Infotainment system manufacturers specifically seek anti shock high clear PET film solutions that maintain their clarity and adhesion properties across wide temperature ranges. The films must also resist degradation from UV exposure and various automotive fluids that may come into contact with interior surfaces during assembly or maintenance procedures.

External Camera and Sensor Protection

Advanced driver assistance systems and autonomous vehicle technologies rely heavily on external cameras and sensors that require protection during vehicle manufacturing and testing phases. These critical safety components cannot tolerate any optical distortion or obstruction that might compromise their functionality. Protective films must provide crystal-clear visibility while offering substantial protection against debris, weather conditions, and handling damage.

The integration of lidar systems and other sophisticated sensing technologies has increased the demand for specialized protective films that do not interfere with various wavelengths of electromagnetic radiation. Manufacturers must ensure that their protective solutions are transparent to specific frequencies while maintaining their mechanical protection properties.

Medical Device and Healthcare Equipment

Diagnostic Imaging Equipment Protection

Medical imaging devices such as ultrasound machines, X-ray systems, and MRI equipment incorporate sensitive display screens that require protection during manufacturing, installation, and maintenance procedures. Healthcare environments present unique challenges, including exposure to cleaning chemicals, sterilization processes, and frequent handling by medical personnel wearing gloves.

The regulatory requirements for medical devices demand that all materials used in their construction meet strict biocompatibility and safety standards. Anti shock high clear PET film used in healthcare applications must undergo rigorous testing to ensure they do not leach harmful substances or interfere with device functionality. The films must also maintain their properties after exposure to various sterilization methods commonly used in medical facilities.

Laboratory Instrumentation and Analysis Equipment

Scientific instruments and laboratory equipment often feature precision displays and optical components that require protection during shipping, installation, and routine use. The demanding environments of research laboratories expose equipment to various chemicals, temperature extremes, and frequent cleaning procedures that can damage unprotected surfaces.

Analytical instruments such as spectrometers, microscopes, and chromatography systems rely on optical clarity for accurate measurements and observations. Any protective film used with these devices must maintain exceptional transparency across relevant wavelength ranges while providing adequate protection against environmental contamination and physical damage.

Industrial Manufacturing and Machinery

Human Machine Interface Systems

Industrial manufacturing facilities increasingly rely on touchscreen interfaces for equipment control and process monitoring. These systems operate in challenging environments with exposure to dust, vibration, temperature fluctuations, and various industrial chemicals. The protective films must withstand these harsh conditions while maintaining touch sensitivity and visual clarity for operator safety and productivity.

Factory automation systems require protective solutions that can endure continuous operation cycles and frequent cleaning procedures. The films must resist degradation from industrial solvents and cleaning agents commonly used in manufacturing environments. Additionally, they must maintain their adhesive properties despite exposure to oils, coolants, and other process fluids that may contact the protected surfaces.

Quality Control and Inspection Equipment

Manufacturing quality control processes rely heavily on optical inspection systems and measurement devices that require pristine visual clarity. These systems often operate in production environments where airborne particles, splatter from machining operations, and handling during setup procedures can compromise optical performance.

Vision inspection systems used in automated manufacturing lines demand protective films that do not introduce optical distortions or artifacts that could interfere with defect detection algorithms. The films must maintain consistent optical properties throughout their service life while providing reliable protection against environmental contamination and incidental contact damage.

Emerging Applications and Market Trends

Renewable Energy and Solar Technology

The solar energy industry has emerged as a significant consumer of protective films for photovoltaic panel manufacturing and installation. Solar panels require protection during production, transportation, and installation phases to prevent damage to their light-collecting surfaces. The films must provide temporary protection while allowing quality inspection of the underlying solar cells.

Wind turbine control systems and monitoring equipment also utilize protective films for their display interfaces. These applications demand materials that can withstand extreme weather conditions, temperature cycling, and exposure to UV radiation over extended periods. The protective films must maintain their clarity and adhesion properties despite these challenging environmental conditions.

Aerospace and Defense Applications

Aircraft manufacturing and maintenance operations require protective films for cockpit displays, navigation systems, and various electronic interfaces. The aerospace industry imposes strict material qualification requirements, including flame resistance, outgassing characteristics, and long-term stability under extreme conditions.

Defense applications often involve specialized requirements for optical clarity, electromagnetic compatibility, and resistance to various environmental stressors. Anti shock high clear PET film used in military applications must undergo extensive testing to ensure compliance with defense specifications and operational requirements across diverse deployment scenarios.

FAQ

What makes anti shock high clear PET film superior to standard protective films

Anti shock high clear PET film offers enhanced impact resistance through specialized polymer formulations and manufacturing processes that create superior mechanical properties. The material combines exceptional optical clarity with improved scratch resistance and dimensional stability compared to conventional protective films. Advanced coating technologies ensure consistent performance across varying environmental conditions while maintaining excellent adhesion characteristics.

How do manufacturers ensure consistent quality in anti shock high clear PET film production

Quality control in protective film manufacturing involves precise monitoring of raw material specifications, coating thickness uniformity, and optical clarity measurements throughout the production process. Manufacturers utilize advanced testing equipment to verify impact resistance, adhesion strength, and environmental stability before product release. Continuous process optimization and statistical quality control methods ensure consistent performance characteristics across production batches.

What factors should be considered when selecting protective films for specific industrial applications

Application-specific requirements include environmental conditions, required protection duration, optical clarity specifications, and compatibility with underlying materials. Temperature range, chemical exposure, UV resistance, and mechanical stress factors must be evaluated to ensure optimal performance. Additionally, removal characteristics, residue-free release, and long-term stability should be considered based on the intended application timeline and end-use requirements.

How is the protective film market expected to evolve with advancing technology trends

The protective film market continues expanding with the growth of electronic devices, automotive displays, and industrial automation systems. Emerging technologies such as flexible electronics, augmented reality displays, and Internet of Things devices create new opportunities for specialized protective film applications. Manufacturers are developing advanced formulations with enhanced functionality, including anti-bacterial properties, self-healing capabilities, and improved environmental resistance to meet evolving market demands.

Table of Contents

- Consumer Electronics and Mobile Device Manufacturing

- Automotive Industry Applications

- Medical Device and Healthcare Equipment

- Industrial Manufacturing and Machinery

- Emerging Applications and Market Trends

-

FAQ

- What makes anti shock high clear PET film superior to standard protective films

- How do manufacturers ensure consistent quality in anti shock high clear PET film production

- What factors should be considered when selecting protective films for specific industrial applications

- How is the protective film market expected to evolve with advancing technology trends